Lorem ipsum dolor sit amet, consectetuer adipis cing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis theme natoque

Study of common formwork methods and coverage units for soffits and fascias

Probably, the simplest form of shuttering is used on the perimeter of a voluminous concrete job, such as a footing or pile cap. The shuttering consists of a sheet or board that covers the side surface, supported by wales parallel to the sides and strutted onto firm ground. Perpendicular (or acute angles between) sheets/boards may be clamped against each other, at corners to prevent separation. Throughput of shuttering is measured in area and the boarding, waling and strutting can be directly or empirically related to the shuttering area. Corner clamps, if necessary should be considered as a separate throughput. This arrangement also is applicable for exposed edges of suspended slabs, sides of drop panels and column heads.

Most construction companies creates an inventory of prefabricated shuttering boards using plywood sheets and wooden runners, for shuttering.

Long members on ground such as grade beams and walls, which require shuttering on two parallel sides, are to be provided with tie rods or strings at intermittent intervals to maintain uniform thickness of concrete. Tie rods provided inside walls ae usually left in place, whereas beam forms are only tied together at top. In all cases, internal corners are also provided with clamps. Customized steel slotted angle sheets or wall form panels are used for formwork of concrete walls. The aforesaid arrangement is also applicable for sides of beams on suspended slabs, in except that base for strutting shall be separately made on cross heads from the props, usually by wooden reapers. Proprietary cross-heads with upstands adjustable according to width of beams are also commonly in use.

PROPREITORY CROSS-HEADS WITH UPSTAND

For vertical members such as columns and piers, two types of arrangements are commonly in use: Prefabricated Boxes and Clamped yoke. Prefabricated forms consist of boards and runners, such as steel column box, wooden box forms or elastomeric lined pier forms. These forms are made in two pieces that are joined together to form a box or desired shape of the pier. Clamped boards use separate shuttering boards for each side of the column/pier and clamped all round by a bolt-through slotted angle arrangement. In either cases, forms are strutted to firm ground, with steel/wooden strut members. More often than not, column/pier falsework, is also associated with a scaffold to provide access to pour concrete. Some arrangements therefore use the scaffold itself to strut and support the column form. Corner clamping is achieved by bolting arrangements between prefabricated shutter surfaces. All items can be directly or empirically related to an area throughput.

Another special case of side shuttering applies to step risers, inverted beams, upstands and top shuttering for steep slopes. The side shutters are either supported on left-in-place chairs or hung from side shutters on other sides.

Soffit shuttering is applicable where concrete is done on an elevated overhead position. Slab soffits are done using prefabricated steel shuttering sheets or wooden poling boards. Size of typical steel shuttering sheet is 915x610mm, although at some locations other sizes such as 1150x610mm are also available. Customarily shuttering sheets are supported along shorter side (spanning longer side) and are able to hold slabs of thickness up to 400mm. Therefore, quantification is independent of slab thickness and type for all practical purposes. However, due to the standardized size of shuttering sheets, some portion of soffit (over and above multiples of steel sheet area) requires to be closed by poling boards.

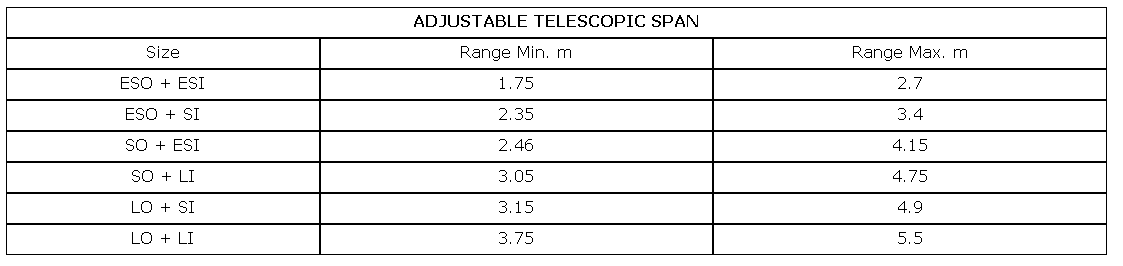

The soffit sheets are supported on typical telescopic shuttering joists (such as acro-Spans) that are available in market. Telescopic joists are commercialized in two or more sizes of outer collapsed length and inner extended length. Many manufacturers make telescopic joists in designations such as ESO, ESI, SO, SI, LO and LI, (standing for Extra-Short, Short or Long & Outer or Inner) as follows:

It can be seen that any slab width can be achieved by one or more rows, with any two types of telescopic joists. Hence, it is convenient to quantify the telescopic joists in numbers of rows required. Manufacturers provide the permissible spacing or allowable loads of joists for each type of telescopic joists. In heavy applications such as bridges, structural steel sections are used instead of typical telescopic joists. In some intensive works, using planks or poling boards instead of steel shuttering sheets, custom-made wooden reapers or runners are used as joists.

It can be seen that any slab width can be achieved by one or more rows, with any two types of telescopic joists. Hence, it is convenient to quantify the telescopic joists in numbers of rows required. Manufacturers provide the permissible spacing or allowable loads of joists for each type of telescopic joists. In heavy applications such as bridges, structural steel sections are used instead of typical telescopic joists. In some intensive works, using planks or poling boards instead of steel shuttering sheets, custom-made wooden reapers or runners are used as joists.

Beam soffits are usually formed, using boards made of plywood and wooden runners. Sometime wooden poling boards and planks are used; very rarely steel shuttering sheets are also used as beam bottom shutters. Plywood or wooden boards or steel sheets are supported on short wooden wales. Commonly crossheads with adjustable upstands are used to support soffits and sides from the props.

Joists are propped at two locations when collapsed or three locations when extended for normal loading conditions. For heavier loading conditions, additional props may be used. Telescopic shuttering props consist of telescopic circular hollow sections, with different clamping arrangements varying among manufacturers. Different height designations (such as 0M, 1M, 2M, 3M and 4M) are used for different applications based on the room height and level of base. Props may have a plate head, suitable for beam formwork, or U-fork head, suitable for telescopic joists for slabs, at the top.

Other customized and proprietary forms of props are also available in the market, such as push-pull props.

“The content presented above is the sole property of Adept Algorithms and shall not be reproduced in part or whole without prior permission”