Bio-Digesters: An Executive Appraisal

Review of recently popular bio-digester systems used instead of conventional septic tanks

Introduction

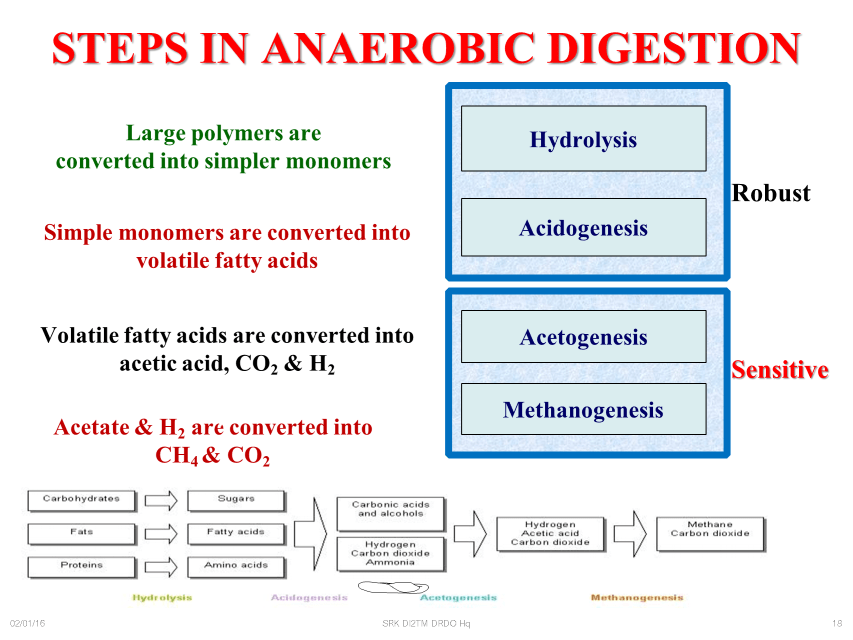

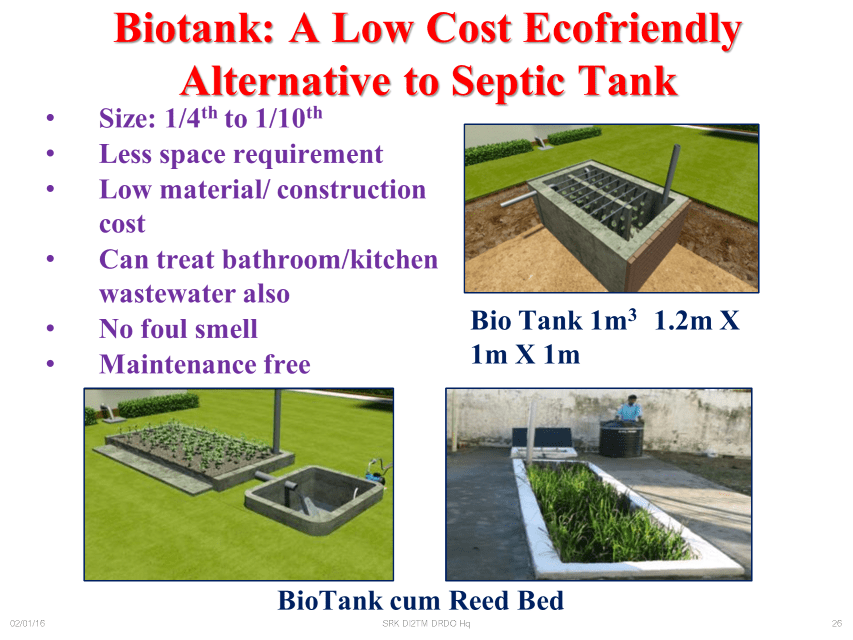

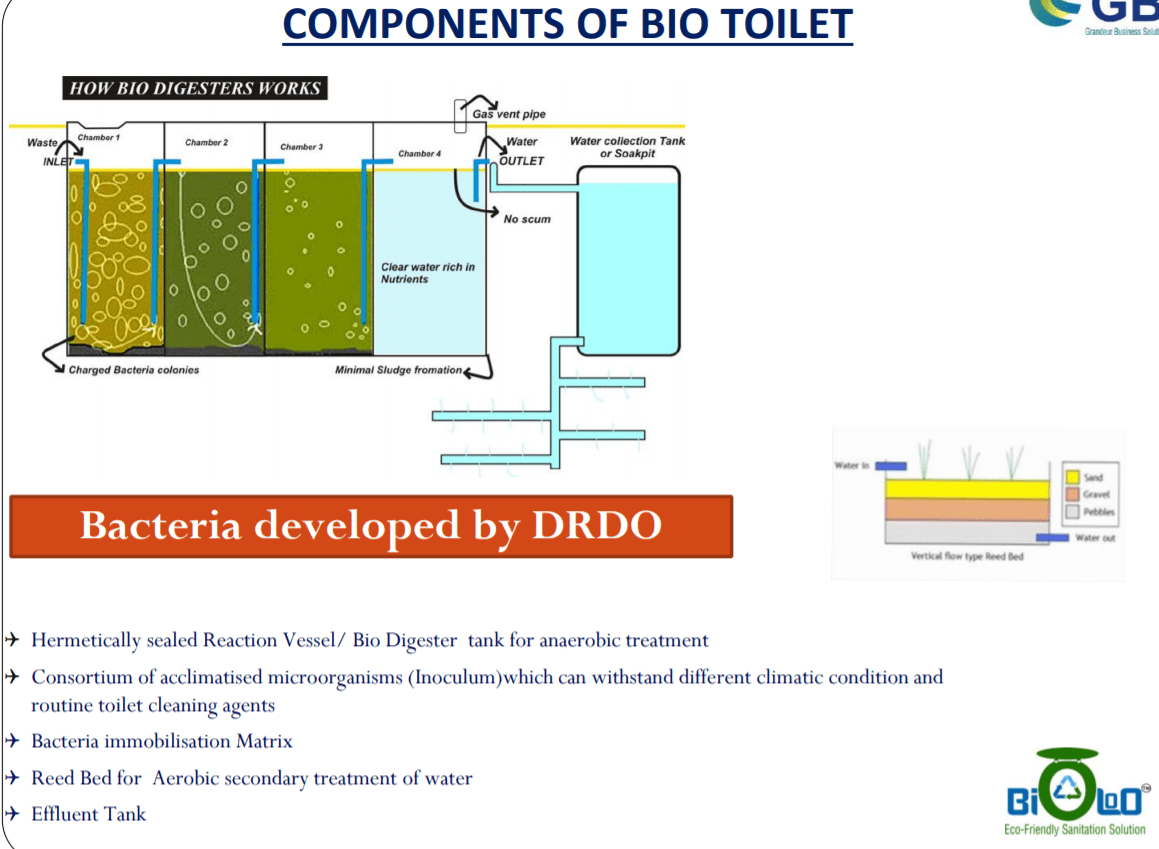

This article presents an executive appraisal of bio-digester systems used in place of conventional septic tanks, for domestic sewage processing. A system that is gaining popularity is developed and promoted jointly by the Defence Research & Development Organization (DRDO) and Indian Railways. This system works through a process called inoculation – wherein a mixture of different species of bacteria, predominantly inoculum genera, is seeded in the sewage collection tank with predetermined quantity of earth and cow-dung. It is claimed that the bacteria are capable of breaking down sludge into predominantly methane, carbon dioxide and water, through a sequence of microbial digestion processes. The gaseous by-products are vented from the tank and treated sewage effluent (TSE) water is tapped from the water for irrigation purposes.

The sewage collection tanks may be underground or on-ground, and may be constructed using reinforced concrete, masonry or FRP material. The oxygen demand and total dissolved solids content of TSE water can further be reduced by providing a filtration system on ground using a reed bed, to meet the quality standards to be directly let into stormwater drains or water bodies. An indication of the arrangement of the bio-digestor, with the advantages of the system is presented in the following figure.

Design Principles

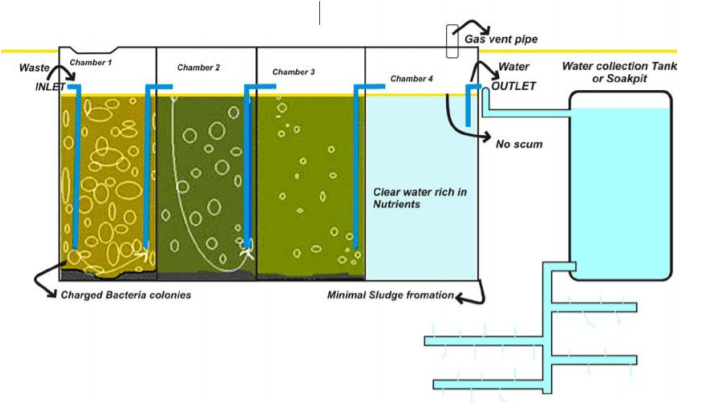

Schematic arrangement of the bio digestor is shown in the following figure:

Conventional septic tanks are designed for holding following volume (excluding freeboard):

- Sedimentation: About 0.3m depth is provided for sedimentation

- Sludge Digestion: Per capita volume of sludge digestion is taken as 32L

- Sludge Storage: Per capita volume if sludge storage is taken as 0.2L per day. For 1-year cleaning, this comes to about 80.3L per capita, including 10% seed sludge.

However, recommendation on Design Specifications is considered based on 14 days holding of sewage volume (@ 80% of 5 LPCD) as 56L per capita. [For Phase 1, this was considered for 2 days holding]

Recommendation from Indian Railways for bio-digester proportioning is 45 LPCD x 72 hours retention = 135 litres per capita (excluding freeboard).

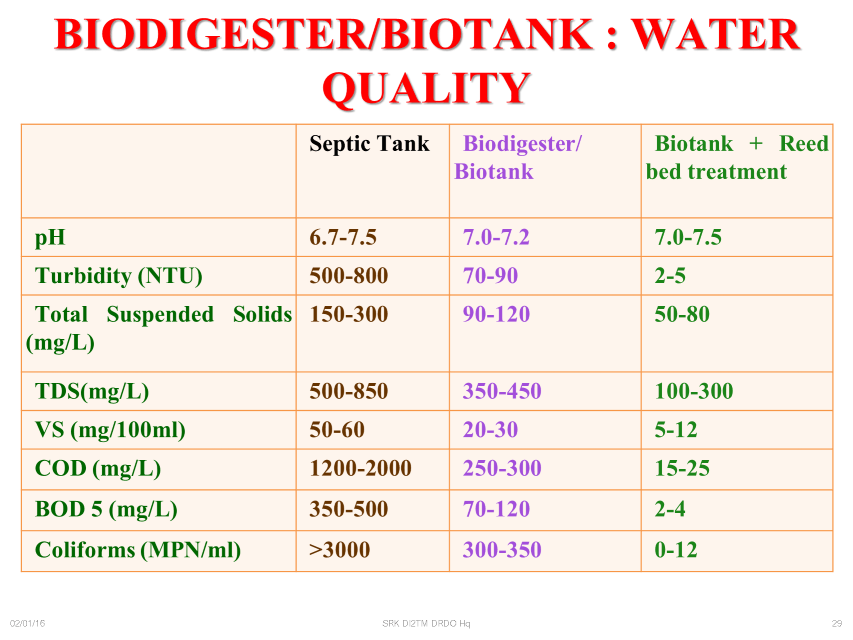

A comparison of effluent water characteristics, as claimed by DRDO is presented as follows:

Limitations of Bio Digestor Systems

- Bio digestor is subject to a set of Dos and Donts to ensure proper functioning. An important limitation is that non-bio-degradable materials such as plastics, glass etc shall not be disposed into the system, as the same results in choking of digestor.

- A 4-year study on stationary bio digest tanks reported in 2017 by IIT Chennai refutes that organic matter does not undergo any kind of treatment in bio-digesters superior to conventional septic tank. Ministry of Defence has, however, questioned the experiment design of IIT Madras and this apprehension has not since been resolved.

- The output water quality Standards need to assessed against the standards of Pollution Control Board, to obtain permissions to let water into groundwater or streams.

- DRDO system is neither patented nor is the chemical equations of organic matter breakdown clearly specified. The design of tank for the bio-chemical processes are based on the thumb-rule style recommendations of DRDO.

Post a Comment

You must be logged in to post a comment.