Concrete: A Management Perspective

Formwork, reinforcements, composition, production, compaction and curing are subject of concrete management.

Concrete is a construction material produced from predominantly inert constituents (called aggregates) and marginal quantities of binding agents (usually cement) and performance-modifying-additives with/without (steel or other) reinforcements, by casting plasticized constituents into moulds and facilitating its solidification by suitable curing. Thus, management of concrete essentially entails management of installation of forms, installation of reinforcement, constitution of concrete, process of production and supply, method of casting and curing.

A method statement for concreting operations should hence address the following aspects:

- Designated/Designed Mix Proportion

- Production Method

- Lifting & Leading Scenario

- Placement Method

- Quality Assurance Procedures

- Arrangements of power and fuel stand-by

Constitution of Concrete

Composition of concrete designated by proportion of (cement: aggregate) constituents, for example 1:1.5:3, is called Nominal Mix whereas composition designated by the grade of concrete such as say 25MPa is called Design Mix. Details of mix proportions for design mix are designed, approved and laboratory-verified by vendors/contractor prior to supply. In recent days, concrete for structural purposes are always specified by design mix. Both nominal and design mix designations are common in non-structural applications.

Although in all cases, the mix proportions are designated in terms of weight, on smaller jobs concrete is also mixed by volume. Volumetric batching is not entertained for grades above 28MPa.

Mix proportion section of method statement should address:

- Grade of concrete for design mix or mix proportions for Nominal mix

- Mix proportions as designed, approved and verified by laboratory tests, for design mix. This is not required for nominal mix.

- Details of approved source of aggregates and brands of cement and other admixtures, if any

Production and Supply of Concrete

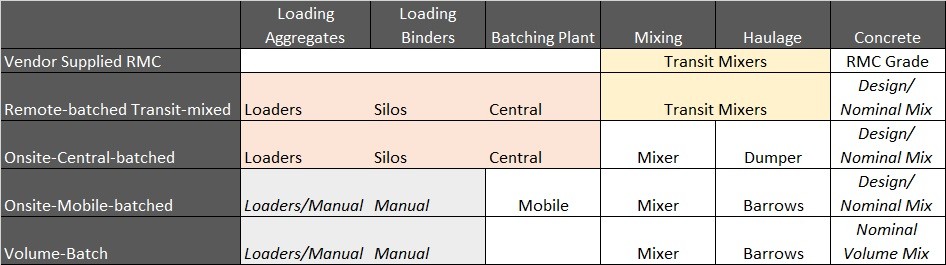

In addition to the conspicuous process of mixing the constituents, concrete production is also supported by other operations such as loading and measurement of constituents for mixing and haulage from mixing location to placement location. Accordingly, there are few different types of production, as follows

The

The

The overall throughput of production, measured by volume, depends on the performance of workforce for each of these individual tasks. We will just look at these individual tasks in detail.

Loading: Constituent aggregates are loaded into the mixer or batcher (or batching silos in centralized batching plants) by manpower or by loader. Cement is loaded manually in site-mixes or pumped into silos in batching plant. If lead of materials from storage location to mixing location is substantial, this effort should be separately accounted. Usually, loading takes place faster than mixing and carriage of concrete, resulting in idling of loader and manpower. Loaders are therefore to be considered as mobilized over the entire duration of batching.

Batching: Constituent materials for concrete is batched either by volume or by weight. A stationary batching plant or mobile batching plant is used when concrete is batched by weight; volume batching is handled using measuring boxes or loading buckets at the site. Working hours of mobile batching plants are in principle proportional to concrete volume, whereas conventionally both mobile and stationary batchers are mobilized over entire relevant duration of project, as mobilization costs are high.

Mixing: Concrete drum mixers are now almost universally used for all concrete works. Performance of mixers are directly related to the throughput of concrete. Where intermittent concrete operations, that are not supplied by ready-mixed concrete, are required, mixers are generally mobilized for monthly hires. Micro-concrete jobs do not involve mechanical mixing.

Transit-Mixer: A transit-mixer is used when the batching plant is located at a distance away from the site, so that mixing takes place while transit by rotation of the drum. The transit mixer performs three stages of operations:

- At the batching plant, transit mixer does not produce any output. Output is solely governed by the capacity of the batching plant. Transit-mixer is always on support to batching plant for this operation, irrespective of its capacity.

- During haulage, transit mixer operates in isolation and depends on the distance and quantity of haulage. Thus for concrete throughput Q and travel time from batching plant to site T, the haulage throughput is QT. If the volume of transit mixer is w units, then the number of transit mixer trips are Q/w engaged for T hours.

- During placement, transit mixer unloading is much faster than the concrete pumping/lifting and actual concrete placement productivity. Unloading is halted when pump/tremie is full, when tremie length is being adjusted or when pump is halted while freshly placed concrete is being leveled. Thus, the transit trucks should stand by during placement of concrete. For continuous placement of concrete, it is necessary that next transit mixer is waiting just-in-time while concrete is placed from one transit mixer. If the placement productivity is q units per hour, transit mixer hours during placement is Q/q.

Therefore, the total transit-mixer-hours required for the project is Q[1/b+T/w+1/q], where b is the batching productivity.

Remote-batched Transit-mixed method is by far, most common in concrete production. It is used for both design and nominal mix. The method shall be characterized by

- Location and capacity of batching plant

- Distance and duration of transit

- Number of transit trucks to be employed and expected arrival time interval

Site-Mixed concrete is predominantly employed on small concreting jobs. It is characterized by

- Deployment of mixer machine

- Deployment of site batcher if any. Site batchers are not used in volumetric nominal mix.

- Deployment of loader or manpower for loading aggregates and cement to mixer (or batcher, as applicable)

Lifting & Leading scenarios

When concrete is associated with a lift (more likely than not) and lead, in addition to its haulage from batching plant to site, the same shall be considered as a separate deployment. Following different scenarios can be identified, along with the factors that are important in management of the scenario.

When concrete is associated with a lift (more likely than not) or lead, in addition to its haulage from batching plant to site, the same shall be considered as a separate scalable or stand-by work. Following different scenarios can be identified:

Concrete Pumping: Concrete pumping is achieved either using a line pump or boom pump. The pump is scalable to the quantity of concrete, whereas tremie pipes needed for conveyance shall be on special-purpose mobilization, to be quantified during take-off. Note that capacity of pump may be affected by the height of lift, which is addressed while selection of pump at specification-time. The factors to be considered for pumps include

- Pump Capacity: Pump capacity depends on type of pumping. Direct-acting, horizontal piston type pump with semi-rotary valves can cover a horizontal distance of 1000 m and a vertical distance of 120 m. The valves open and close with definite pauses so that concrete moves in a series of impulses, but the pipe always remains full. These pumps are capable of pumping 130 m3 of concrete per hour with 8 inch pipes. Squeeze or peristaltic pumps or vacuum pumps can cover a distance of 90 m horizontally and 30 m vertically. They are capable of pumping 20 m3 of concrete per hour using 3 inch pipes.

- Length/number of tremie pipes in line pumps and boom length in boom pumps: Bends in tremie pipe setting causes extensive losses in pumping – every 10 degree bend is equivalent to an extra length of pumping of 1 m.

- Arrangements of control of tremie choking: The pipe diameter should be at least 3 times the maximum aggregate size as large aggregates tend to choke near the bends. A larger slump is preferred for pumpable concrete. Note that pumping induces partial compaction, so the slump at delivery point is decreased. The economy of pumping depends on the number of interruptions. Each time, the priming of the pipes using mortar is required (0.25 m3/100 m of 6 inch pipe), and the pipe also has to be cleaned.

Too much voids in concrete can push water alone through these voids during pumping. Therefore, mix proportioning, especially grading of aggregates, of pumpable concrete is important to prevent segregation of concrete during pumping.

Hoist/Tower Crane: Ignoring the time of operation of hoist/crane (by loading large barrows in hoists/cranes) manpower may be required to move material to and from hoist/crane, which may be addressed using a leading scenario.

- Mobilization of hoist/crane

- Manpower required to move material to and from hoist/crane

Manual lifting by relay transfer: The total distance of lead/lift is used to determine the number of unskilled helpers required for a relay transfer. The speed of transfer is weight-of-parcel / interval-between-parcels. Any scaffolds or access ladders required for transfer shall be on direct mobilization.

- The total distance of lead/lift

- Number of unskilled helpers required for a relay transfer

- Any scaffolds or access ladders required for transfer

Method of Placement

Simple discharge: Simplest form of concrete placement occurs in cases such as piling concrete, micro-concrete and self-levelling self-compacting concrete where concrete is directly tipped off from transit mixer or carried on barrows from site-mixer to point of discharge. No workforce is actually involved in the act of placing

+ Vibrator: Incrementally, cases such as columns, footings, walls and other cases with geometry confined by formwork on all directions, concreting is also associated with vibration, in addition to discharge. Vibration is achieved most commonly by internal needle vibrators, and is characterized by the type and number of vibrators. Needle vibrators (40mm) operate on about 0.25sqm influence area, 400mm (10d) immersion depth for 30s-2min – this makes its capacity to be 8-12 kL/h.

+ Levelling Manpower: On suspended slabs and mass concrete applications, manpower is required for levelling of concrete, including leveling guages, strings and control markers. Sometimes, this may be associated with leveling survey instruments. Levelling and compaction although may not be analytically related to concrete throughput, empirical relation can be evolved for this purpose. Besides, it is necessary to maintain adequate speed of laying to prevent choking of concrete in the pump pipes. Placement speed of 12-16 kL per hour is quite common in the industry.

Special Cases of Placement

Other cases of concreting activities not mentioned here includes shotcrete, roller compacted concrete, mass concrete, micro-concrete etc.

A special case of application is placement of screeding concrete, where concrete is laid on grade or flat surfaces. Two methods are commonly employed for screed concrete:

- Screed Vibrator: In this conventional method, concrete grade slab is levelled on grade with a screed vibrator that runs on prefixed rail channels. The rail channels are fixed on the grade after placing the reinforcements, such that concrete can be poured in alternate bays at a time. The channels act as the guage that controls the thickness of concrete. The screed vibrator compacts the concrete and is subsequently followed by removal of excess water using vacuum dewatering. The floor surface is then polished to required surface finish using a power trowel, with required finishing tools. The remaining alternate bays are poured in the next session, leaving a construction joints with the previously laid alternate bays.

- Laser-controlled screeding machine: Laser controlled screeding machine does not require channels rails or guages. The machine is capable of controlling the level of concrete grade slab to reasonable thickness using laser beams. Screeding is followed by vacuum dewatering and power trowel based on the requirement of the project. Vacuum dewatering is now being progressively replaced by use of surface hardening additives.

Quality Assurance Mobilizations

Mobilizations required for quality assurance for concrete applications are as follows:

- Batching reports, where applicable

- Sampling cubes: Number of cube moulds at origin and site

- Slump cone and workability testing apparatus

- Level guages and instruments

- Cube compression testing machines

“The content presented above is the sole property of Adept Algorithms and shall not be reproduced in part or whole without prior permission”

Post a Comment

You must be logged in to post a comment.